Are you aware of the role of medical manufacturing? Without this sector, we won’t be able to survive several things as we won’t have the proper equipment and tools to proceed further. But still, nobody talks about it.

According to ResearchGate, “The global medical devices market was valued at US$550 billion in 2021 and is expected to reach US$850 billion by 2030, poised to grow at a compound annual growth rate (CAGR) of 5.5% during the forecast period 2022–2030”

In this article, I’ll give you a detailed overview of medical manufacturing and why it is the unsung hero of the health industry.

Manufacturing plays a huge part in healthcare through the production of medical devices and tools. This field is not only limited to surgical instruments, it also makes implantable devices for biopharmaceuticals

Medical professionals are highly dependable on specialized tools as they help them with performing procedures on patients and taking care of them. These equipments need to be of high quality as they’ll be used on people to improve their conditions.

Manufacturers work hard in design, development, production, quality control, and regulatory compliance. These steps are conscientiously executed to produce the best quality products that meet strict safety and efficacy standards.

This is a meticulous approach ensured by manufacturers to ensure that medical products are safe and durable for patient use.

Just as the medical field has various crucial elements in healthcare, so does the manufacturing industry, which makes a multitude of products for the medical industry. It ranges from bandages to complex surgical machines and tools.

General and essential items like syringes, gloves, and personal protective equipment (PPE), such as disposable aprons, are commonly produced by manufacturers for medical use.These are used across different medical procedures, checkups, and patient care.

They serve to protect the health professionals as well as their patients and provide needed health services.

Technologies that aid in surgical procedures are produced by several device manufacturing companies. This includes scissors, retractors, scalpels, suction tools, clamps, and more.

As medical device manufacturing produces better equipment, the quality and precision of healthcare also improve.

Another aspect of healthcare is medical diagnosis. Health professionals will use different devices and equipment to look at patient symptoms and diagnose issues. Healthcare professionals can analyze different areas of patients with the help of diagnostic equipment.

The better quality and more accurate the equipment, the better the diagnosis. Diagnosic devices cover simple equipment to complex machines. Basic diagnostic devices like stethoscopes, thermometers, otoscopes, and scales are also used by health care experts. Machines like centrifuges, ultrasound, monitors, and electrocardiographs are also utilized.

Several procedures heavily rely on medical devices to eliminate or fix any health-related issue. These medical implants are synthetic and placed in or on a patient’s body to help their health. To make these instruments reliable and compact, they went through a detailed engineering process.

Pacemakers, cochlear implants, stents, surgical mesh, dental implants, and artificial joints are examples of these medical implants. Patients are able to achieve higher quality of care thanks to medical implants, which were only possible because of medical device manufacturing.

In the infographic below, you can see the top pharmaceutical manufacturing countries in the world.

Different materials are used to create medical equipment and devices, such as the Teledyne LABS autosamplers. The manufacturing process also varies from tool to tool. Like injection molding, which is a manufacturing process used especially for plastic products. It simply melts plastic pellets into a liquid and shapes it.

Metal fabrication is another crucial process and a huge part of this sector. It creates the metal components so that devices can be operated properly. It adds strengths and lowers the manufacturing cost.

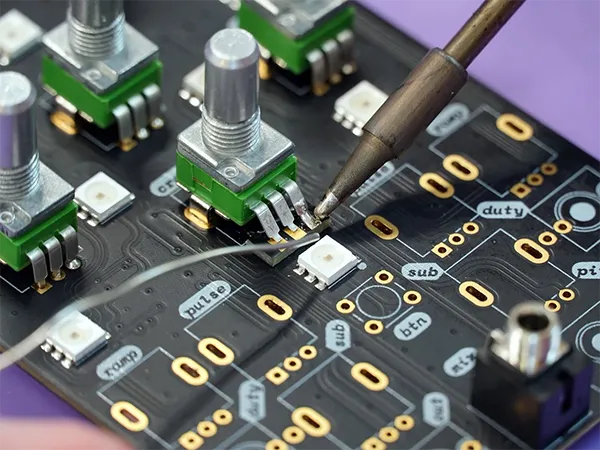

There’s also a circuit board assembly without it the electric tool won’t function and is as important as the other two operations.

Nobody can disagree that medical manufacturing i as important as any other thing. After all, it ensures successful surfers and other procedures. High-quality medical devices help improve patient prognosis and recovery.

With the integration of advanced techniques, medical manufacturing has developed cutting-edge devices that give even better performance and accuracy.

These tools are only made by reputed manufacturing companies, they also pass several tests to maintain safety standards. Such items augment the capabilities of professionals to help patients and save lives.

DID YOU KNOW?

In 2023, the U.S. exported medical tools worth $36.6 billion, no other country was able to do so!

Medical manufacturing can’t be replaced and is the core of the health industry. It saves millions of lives and takes care of those in need.

When medical facilities look to provide the best care, they need the best medical manufacturing by a company like High Tech Quality Manufacturing. To sum it up, they are no less than heroes of the medical world because they produce life-saving items.

Their products help professionals to be as efficient as possible in providing proper medical services. Now you are aware of their role and why it can’t be overlooked. A world without this sector would be in great danger, that’s for sure.