KEY TAKEAWAYS

- Droplet microfluidics enables thousands of rapid, miniaturized reactions per second.

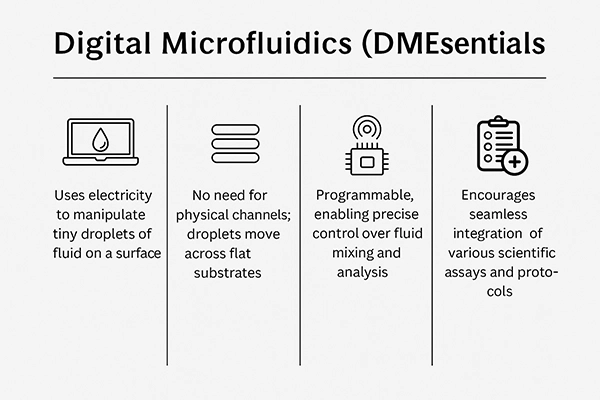

- Digital microfluidics offers programmable, low-power assays on a credit-card chip.

- Acoustic liquid handling reduces waste with touchless, nanoliter-scale dispensing.

- High-density microplates cut reagent use and increase throughput dramatically.

As detailed in a MarketandMarkets report issued in 2023, the global lab automation industry is expected to rise to $9 billion in 2030. Various factors are causing the increased demand for quicker and less expensive testing solutions.

We are moving from kiloliter volume limits to femtoliter volume limits, and that is fundamentally changing diagnostics, drug discovery, and molecular biology. The focus of advances in assays continues to shift to tools that allow for miniaturization to occur, and engineers have begun to deliver on more traditional assays that are both precise and scalable and can transform labs and hospitals.

The main goal of this article is to take a look at the five most prominent technologies moving the future of assay miniaturization forward, each one accompanied by a description of real-world use cases.

Continuous-flow droplet microfluidics traps reactions within water-in-oil emulsions produced and processed at kilohertz-level frequencies. Each droplet acts as a nanoreactor, holding femto- to nanoliter volumes—10³–10⁶-fold less than a 96-well plate yet capable of running thousands of parallel chemistries per second. Because reagents and analytes remain segregated by the carrier oil, cross-talk is minimal and reaction kinetics are quickened by short diffusion paths. Recent studies in Lab on a Chip report droplet HTS platforms reaching >500 Hz manipulation speeds while slashing reagent expenditures by up to 99 % compared with robotic liquid handlers.

Where droplet microfluidics flows, DMF steps. Instead of channels, DMF uses patterned electrodes (electrowetting-on-dielectric) or, more recently, magnetically driven PCB coils, to shuttle individual droplets across a flat substrate like chess pieces on an electronic board.

A 2025 study in Nature Microsystems & Nanoengineering demonstrated fully customized magnetic DMF with built-in electrochemical sensors that detected glucose in sweat—no optics, no pumps, no high voltages.

The outcome: energy-efficient chips that mix, split, and examine sub-microliter samples with smartphone-like control and real-time data transmission. For assay developers this means walk-away automation of complex, multi-step workflows in the footprint of a credit card. Below, you can see the essential things you’ll be needing.

Assay miniaturization stalls if pipette tips refuse to shrink. Enter acoustic droplet ejection (ADE)—a contact-free method that focuses ultrasonic waves under a microplate well to launch 2.5-nL droplets upward into a receiving plate.

Because nothing touches the fluid, there is zero tip carry-over, virtually no dead volume, and reagent costs plummet. A 2024 report in SLAS Technology evaluated ADE for cell-based HTS with natural-product libraries, achieving consistent Z′ > 0.7 at a tenth of the usual volume.

When paired with 1536- or 3456-well plates, ADE supports screening densities once reserved for in silico campaigns, bringing ultra-high throughput back to the wet lab.

While microfluidic chips steal the headlines, classic plate formats quietly evolve. Vendors now supply 6144-well plates, nanowell slides, and even encoded particle arrays that compress entire dose-response curves into a square centimeter. These platforms dovetail with ADE and DMF: acoustic dispensers fill the wells, and droplet optics or CMOS imagers read them en masse.

The economics are brutal—in a good way. Cutting a 384-well enzyme assay from 20 µL to 1 µL in a 3456-well format uses 95 % less reagent, slices tip waste to zero (with ADE), and fits nine plates where one used to sit in the incubator. Adoption accelerates most in combinatorial chemistry and CRISPR guide-RNA screening, where library size—not sample volume—is the limiting factor.

The newest frontier combines additive manufacturing with automated sensing. By printing microfluidic circuits directly around electrodes, photodiodes, or even nanopore detectors, engineers create self-reading chips—no external plates, pumps, or optics are needed.

Recent prototypes marry 3D-printed channels with thin-film electrochemical arrays to monitor enzymatic kinetics on-chip, using tens of nanoliters per reaction and streaming the data straight to cloud LIMS.

The flexibility of resin-based printing means researchers can iterate device designs overnight, rapidly customizing mixers, gradient generators, or chemotaxis mazes without the costs of photolithography. For pharma, this points to bespoke chipsets that travel with each project, reducing technology transfer risk and accelerating lead-optimization cycles.

Each platform solves a different piece of the miniaturization puzzle: droplet microfluidics maximizes parallelization; DMF helps automate complex workflows; ADE removes the physical barriers of tips; ultra-dense plates provide a broader format; and printed chips with indicators close the data loop. Individually, they deliver 10- to 100-fold savings; combined they rewrite experimental economics:

By 2030, the default “micro” assay may occupy femtoliters, not microliters. Future roadmaps include AI-driven droplet routing, roll-to-roll printed microfluidics for disposable diagnostics, and hybrid acoustic–digital platforms that design their own plates mid-run.

For now, utilizing even one of the five technologies above can reduce timelines and budgets. Using several together can uncover biology previously unapproachable.

Miniaturization isn’t just about doing the same experiments with less—it’s about asking bolder questions because the cost of a bad idea is suddenly affordable. The sooner those questions move from whiteboard to nanoliter, the faster discovery will happen.

It allows for thousands of small, rapid, parallel chemical reactions using femto- to nanoliter droplets with a minimal amount of cross-contamination.

It uses sound waves to apply small droplets similar to a tip, eliminating tips thus eliminating waste as well as cutting down on reagent cost drastically.

They integrate sensors into the device and reduce the amount of equipment you need, realize real-time low volume analyses of chemicals as well as minimize development time and redesigns.